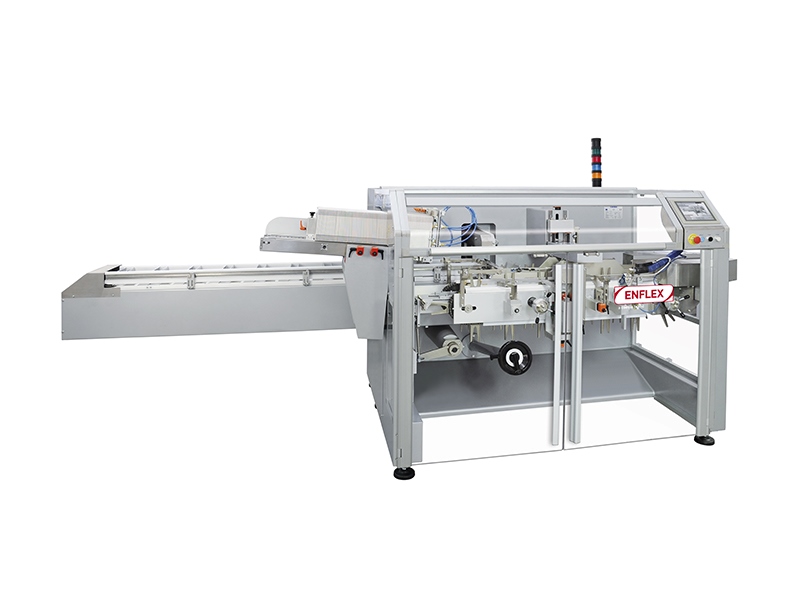

HFFS Machines

Enflex Horizontal Form Fill Seal machines deliver complete packaging solutions for pharmaceutical, supplement, and food applications.

Horizontal Form Fill Seal. Horizontal Execution.

Horizontal machines are known as HFFS, an acronym that stands for Horizontal Form Fill & Seal. Starting from a reel of flexible packaging, the machine forms the pouches, fills them, and seals them at the top, with the pouch traveling horizontally across stations.

Each station is designed for a specific purpose and is independently adjusted without affecting the performance of other stations.

The sealing stations are separated from the filling area, eliminating interference between sealing and dosing.

Horizontal FFS machines are distinguished by the quality of pouches manufactured, air-tight seals, and exceptional surface finishing.

Flat Sachet / Flat Pouch Machines

Horizontal form fill seal machines for sachet and pouch production

Enflex F-11

Compact intermittent horizontal packaging machine ideal for small to medium production runs. Perfect for pharmaceutical sachets and single-dose packaging with reliable performance.

- Up to 120 sachets/min

- Compact footprint

- Easy format changeover

Enflex F-14

Mid-range intermittent horizontal packaging machine with enhanced speed and flexibility. Suitable for powders, granules, and liquid products with servo-driven precision.

- Up to 180 sachets/min

- Multi-format capability

- Servo-driven systems

Enflex F-17

High-performance intermittent HFFS machine designed for demanding production environments. Features advanced control systems and superior reliability with quick-change tooling.

- Up to 240 sachets/min

- Advanced HMI interface

- Quick-change tooling

Enflex PH-28

Premium continuous motion horizontal packaging solution for high-volume pharmaceutical production. Maximum efficiency with minimal downtime and automated quality control.

- Up to 300 sachets/min

- 21 CFR Part 11 compliant

- Automated quality control

Towelettes / Wet Wipes Pouches

Specialized horizontal packaging machines for wet wipes and towelette applications

Enflex F-11 TW

Compact intermittent wet wipes packaging machine for small to medium production volumes. Ideal for personal care and hygiene product manufacturers requiring reliable towelette packaging.

- Up to 120 pouches/min

- Wet product handling

- Hermetic sealing

Enflex F-14 TW

Mid-range intermittent wet wipes machine with enhanced speed and versatility. Perfect for personal care, cosmetic, and hygiene applications with servo-driven precision.

- Up to 180 pouches/min

- Multi-format capability

- Servo-driven systems

Enflex F-17 TW

High-performance intermittent wet wipes packaging machine for demanding production environments. Advanced control systems with superior reliability and quick-change tooling.

- Up to 240 pouches/min

- Advanced HMI interface

- Quick-change tooling

Integrated Cartoning Solutions

Downstream automation integration for complete packaging lines

Enflex PK-225

Intermittent side-load cartoner for pouches or stick packs up to 60 cartons per minute. Compact design ideal for smaller production runs with reliable performance.

- Up to 60 cpm

- Side-load design

- Compact footprint

Enflex PK-222

Intermittent side-load cartoner for pouches or stick packs up to 90 cartons per minute. Versatile mid-range solution with servo-driven precision and easy format changeover.

- Up to 90 cpm

- Servo-driven precision

- Quick format change

Enflex PK-221

Intermittent side-load cartoner for pouches or stick packs up to 120 cartons per minute with pharmaceutical design. High-speed solution featuring advanced automation and integrated quality control systems.

- Up to 120 cpm

- Pharmaceutical design

- Automated quality control

Why Choose Enflex HFFS?

High Speed

Up to 300 sachets per minute

Precision

Accurate dosing and sealing

Flexibility

Quick format changeovers

Compliance

FDA and GMP standards

Need Help Choosing the Right HFFS Solution?

Our experts can help you find the perfect packaging line for your production needs.

Contact Us Today